Quality

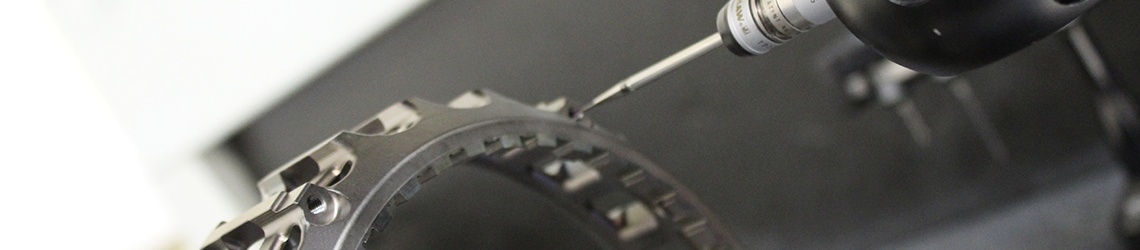

Quality control is just as important to Whiteley Brooks as it is to you, we have a fully equipped inspection department. This includes 3 three axis CMMs with motorised heads, consolidates the company’s commitment to quality providing full inspection reports and certification where required.

It is in line with this philosophy that Whiteley Brooks Engineering has its quality management system assessed and registered to ISO9001:2015. Our original assessment and certification was achieved in 1995. Our Quality Management System is audited by SGS.

Our full traceability service allows us to identify each individual procedure in the manufacturing process.

Our new purpose built inspection facility includes two state of the art Coordinate Measuring Machines and our new computer linked photographic microscope.

All of our CMM machines have been re-furbished by Renishaw and now run Renishaw’s Modus Software enabling inspection to be performed against models created by most leading CAD Software Houses.

Our inspection department has recently invested in a Quantum M Faro Arm. This has a laser scanner attachment, it uses polyworks software, which allows our engineers to check complex contours and surfaces. We can also reverse engineer parts by inspecting directly from CAD data.

Whiteley Brooks have maintained an A1 rated vendor status to Hartridge Ltd, since October 2006. Their attention to detail and professional attitude makes for a perfect partnership.

CNC Milling and Turning Machines

-

- 5 Doosan DNM 5700 with 5th axis capability

- 9 Bridgeports with 4th axis capability

- 10 Hardinge Bridgeport with 5th axis capability

- 6 Hardinge Bridgeport with 4th axis capabilty

- 1 Mazak Variaxis 5 Axis Machining Centre

- 3 Kia CNC Lathes (Maximum Diameter 380mm)

- 2 Doosan CNC Lathes (Maximum Diameter 360mm)

- 3 Doosan Puma 2600 CNC Lathe (Maximum Diameter 480mm)

- 1 Doosan Lynx 220 CNC Lathe (Maximum Diameter 270mm)

- 1 Doosan Lynx 300 CNC Lathe (Maximum Diameter 400mm)

- 1 Doosan GT2100 CNC Lathe (Maximum Diameter 390mm)

- 1 Doosan Puma GT 2100M Lathe (Maximum Diameter 360mm with Live Tooling)

- 1 Doosan Puma GT 2600 Lathe

Conventional Machinery

- 5 Centre Lathes

- Pollard 4 Spindle Drill Press

- Jones and Shipman 1300 Universal Grinding Machine

- Jones and Shipman 540 Surface Grinder

- Snow Tub Grinder

- Speedhone Hone

- 2 Vibro Engraving Machines (ProPen)

- 1 Laser Marking Machine (Technifor)

- 2 Forklift trucks

- 2 KELCH i-tec Heat Shrink

- 1 Kasto Band Saw

- 1 Vertical Band Saw

- 1 Pedrazzoli Circular Saw

Inspection Equipment Includes:

- 3 Axis Manual Coordinate Measuring Machines

- 2 x 3 Axis CNC Coordinate Measuring Machines with Renishaw Modus CAD Software, allowing our quality engineers to work from customer solid models

- 5 Axis CNC Coordinate Measuring Machines with Renishaw Modus CAD Software, allowing our quality engineers to work from customer solid models

- 2.5M, Quantum M, 8 Axis Faro Arm running on Polyworks software

- Mitutoyo Shadowgraph

- Full Range of Micrometers and Verniers

- Granite Surface Plates

- Microscope and Measuring Software

- Full Range of Gauges and General Measuring Equipment

- Venda 365 gauging unit

- Starrett 400 series shadowgraph

Wiring

- Agie Charmilles Cut 20P Wire eroder

- Agie Charmilles Cut E 600 Wire eroder